Wood Plastic Composite (WPC): What is that?

Wood Plastic Composite (WPC) is an innovative material that combines the aesthetics of wood with the durability of plastic. It offers an attractive alternative to traditional wood products, especially in outdoor applications such as terraces, cladding, garden furniture and fences. In this blog, we dive deeper into the properties, manufacturing processes, benefits, applications, and considerations when using WPC.

What is WPC?

Wood Plastic Composite is a composite fabric made up of natural fibers, such as wood flour or bamboo, combined with thermoplastics such as polyethylene (PE) or polypropylene (PP). This combination creates a material that has the appearance of wood, but with improved performance in terms of durability and maintenance. The most common combinations between natural fibers and thermoplastics are:

- 60% Wood Dust / 35% Plastic / 5% Additives:

This ratio is common in WPC products and offers a balance between aesthetics and functionality. - 50% Wood Fibers / 50% Plastic:

An even distribution that ensures a natural look while retaining the advantages of plastic. - 50% Houtmeel / 50% Polyethyleen (PE):

A popular combination in the North American market, where PE provides flexibility and moisture resistance.

Production Process of Wood Plastic Composites (WPC)

The manufacture of Wood Plastic Composites (WPC) is mainly done through an extrusion process, in which a carefully composed mixture of natural fibers and plastics is combined under high temperature and pressure. This process creates a strong bond between the components, resulting in a homogeneous and stable final product.

Mixing process

In the first stage, the natural fibres, such as wood flour or bamboo, are combined with thermoplastics such as polyethylene (PE) or polypropylene (PP). These materials are mixed together with additives such as dyes, UV stabilizers and flame retardants. Additives such as lubricants improve the workability and appearance of the surface, while coupling agents strengthen the bond between the wood fibers and the plastic matrix.

Extrusion process

The homogeneously mixed material is then fed into an extruder. The extruder heats and transports the mixture, resulting in a molten mass. This mass is pressed through a mould that forms the WPC into the desired profile shape, such as planks, panels or other shapes. This process determines the dimensions and texture of the final product.

Cooling and finishing

After extrusion, the formed profile is cooled to solidify the material and maintain its shape. Once the WPC has hardened, it is cut to the desired length and can undergo additional finishing processes such as sanding or surface treatments. These treatments improve both the aesthetics and functional properties of the final product.

By precisely controlling the mixing and extrusion process, as well as the use of specific additives, manufacturers can produce WPC materials that meet various functional and aesthetic requirements.

Benefits of WPC

- Durability and resistance to environmental factors: WPC can withstand a variety of weather conditions, including rain, snow, and intense solar radiation. The material is resistant to mold, rot, and insects, which contributes to a longer lifespan without the need for regular maintenance. In addition, its resistance to UV radiation ensures that the color of the material is preserved.

- Ease of maintenance: Unlike traditional wood, WPC requires minimal maintenance. Periodic cleaning with water and mild soap is usually sufficient to keep the material in optimal condition. This saves time and costs that would otherwise be spent on painting or staining.

- Eco-friendliness: WPC is often produced with recycled materials, which contributes to a circular economy and helps reduce waste. The use of recycled plastics and wood fibres reduces the demand for virgin raw materials, which is positive for the environment.

- Aesthetic flexibility: WPC offers a wide range of colors, textures, and finishes, which gives designers and homeowners the freedom to customize the material to suit different aesthetic preferences and styles. Whether it's a modern, sleek look or a more traditional look, WPC can meet a variety of design needs.

Versatile applications

WPC is a versatile material that is used in various sectors and for different applications:

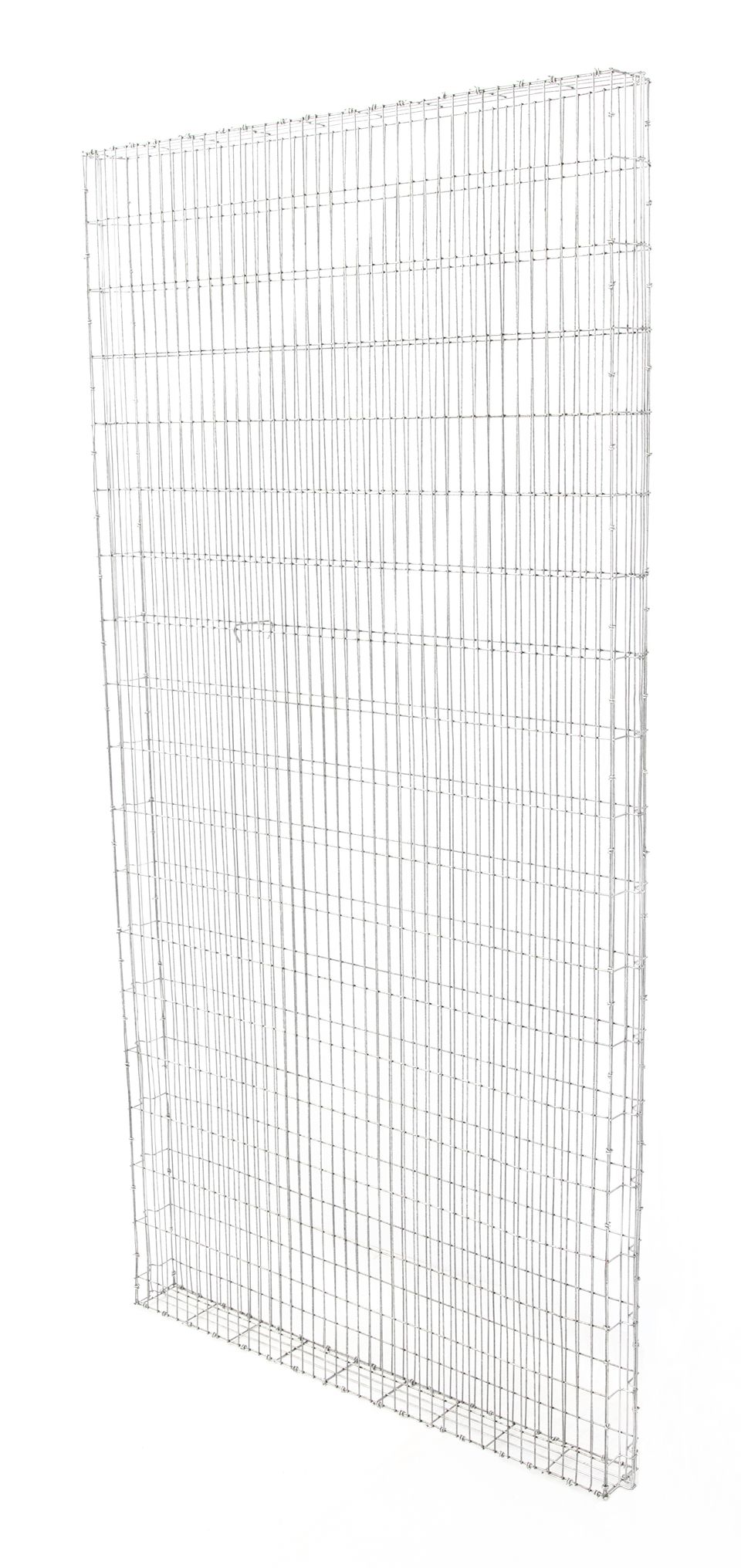

- Fences: WPC fences combine aesthetics with functionality, which makes them an excellent choice for garden fences.

- Deck Constructions: WPC decking/tile offers a natural look with the benefit of durability and low maintenance. They are slip-resistant and resistant to weather influences.

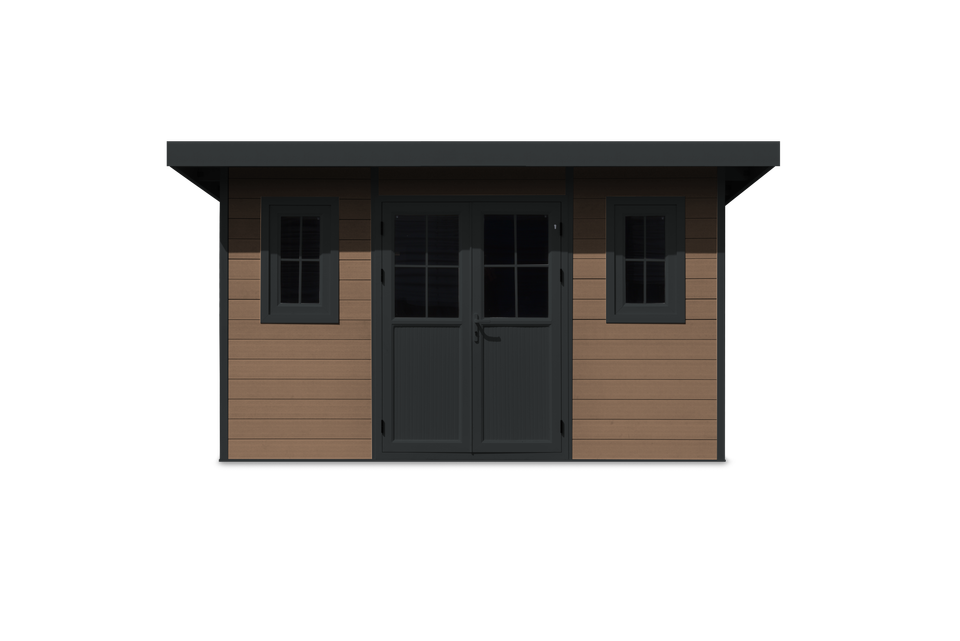

- Façade cladding: WPC façade panels combine aesthetics with functionality. They contribute to the energy efficiency of buildings through insulating properties and are available in various styles and finishes.

- Garden furniture: Furniture made of WPC is weather-resistant and retains its color and structure.

Considerations for Using WPC

While WPC offers many benefits, there are some considerations to consider when choosing this material:

The initial cost of WPC products can be higher than that of traditional wood alternatives. However, given the lower maintenance costs and longer lifespan, WPC will be a cost-effective choice in the long run.

WPC can absorb heat, which means that darker colors feel warmer when exposed to direct sunlight. This can affect comfort in use, especially for applications such as terraces or garden furniture. It is advisable to take into account color choice and location to optimize thermal comfort.

Although WPC requires less maintenance than traditional wood, it is not completely maintenance-free. Regular cleaning with warm water and a mild vinegar-based cleaner is recommended to maintain aesthetics. It is also important to follow the manufacturer's installation instructions to ensure the longevity of the product.

Conclusion

Wood Plastic Composite offers an attractive combination of the natural look of wood and the durability of plastic. It is a versatile material that is suitable for various applications, both indoors and outdoors. When considering WPC for your projects, it's important to consider both the benefits and potential limitations so that you can make an informed choice that aligns with your specific needs and sustainability goals.